Fluimac Pneumatic Dampers – Smooth, Silent, Surge-Free Flow

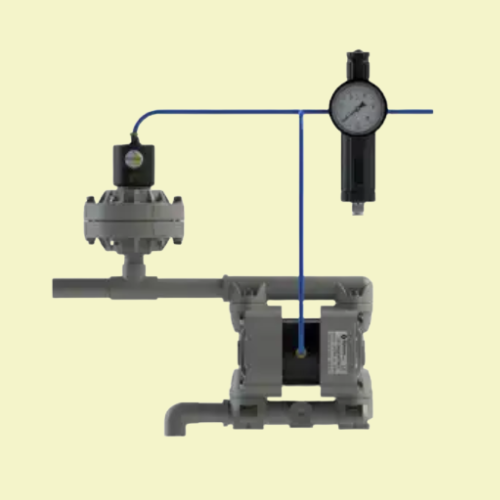

Diaphragm pumps often produce pulsations in fluid flow, leading to pressure fluctuations and potential system instability. GM PUMPS proudly supplies Fluimac pneumatic dampers as a high-performance solution to this challenge, effectively minimizing pressure oscillations during the pump’s discharge cycle.

These dampers significantly reduce pulsation and water hammer effects, while also dampening vibrations transmitted by the diaphragm pump. Operating with compressed air, the Fluimac damper automatically adjusts to maintain optimal pressure, ensuring smooth and consistent flow without manual calibration.

Designed for durability and ease of use, Fluimac dampers require minimal maintenance and are available in the same material configurations as the pumps they support. Thanks to their cutting-edge technology, they can reduce flow pulsation by up to 90%, self-regulating in real time to match the fluid dynamics within the delivery line.

GM PUMPS integrates these dampers into advanced fluid handling systems across chemical, water treatment, and industrial applications—delivering reliable performance and modular compatibility with Fluimac diaphragm pumps.

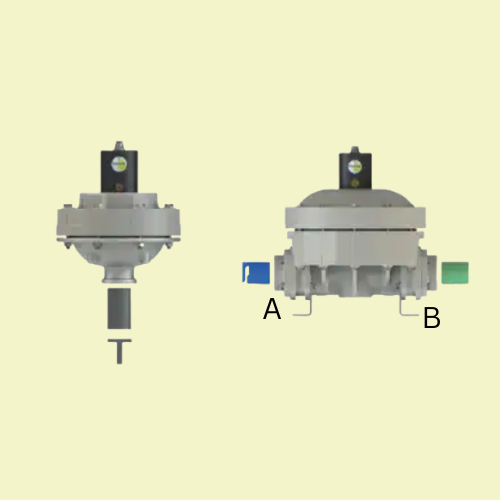

APPLICATION AREAS DAMPER RANGE

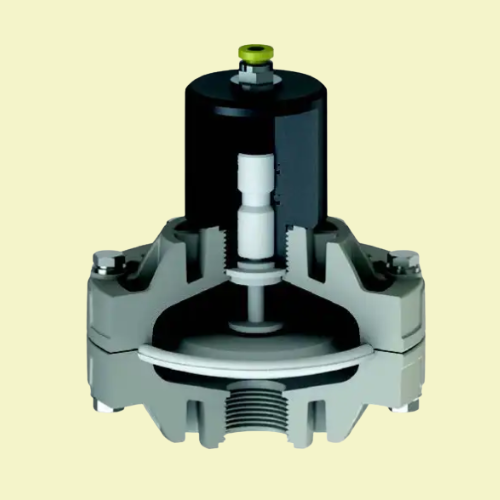

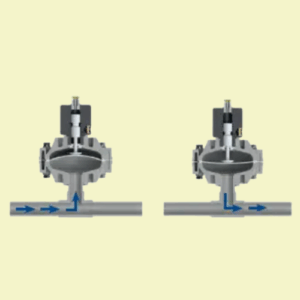

How it works

GM Pumps’ engineered diaphragm system delivers precision flow control.

At GM PUMPS, innovation meets precision in fluid control.

Our advanced system harnesses the energy of pulsating discharge flow to drive the diaphragm upward, where it is gently cushioned by compressed air within the pneumatic chamber.

This controlled diaphragm flexing effectively dampens pulsations, ensuring a smooth and continuous fluid flow. In applications with pressure feedback, this design achieves a remarkable 70–80% reduction in pulsation pressure, delivering consistent performance and protecting downstream components.

APPLICATIONS

MEASUREMENT AND DOSING: Dampens discharge pressure peaks, increasing accuracy.

FILTER PRESS Increases the efficiency and operating life of filters.

SPRAYING Smooth, consistent spray pattern.

FILLING Eliminates filling errors and splashes.

TRANSFER Eliminates damaging water hammer, safeguarding pipes and valves.

Add Your Heading Text Here

INSTALLATION

PORT POSITION